I. Food Processing Industry Solutions

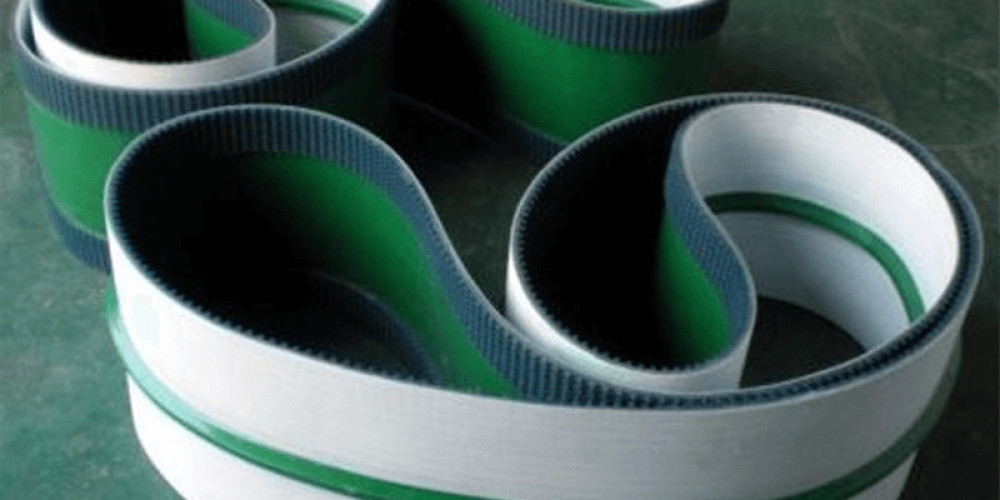

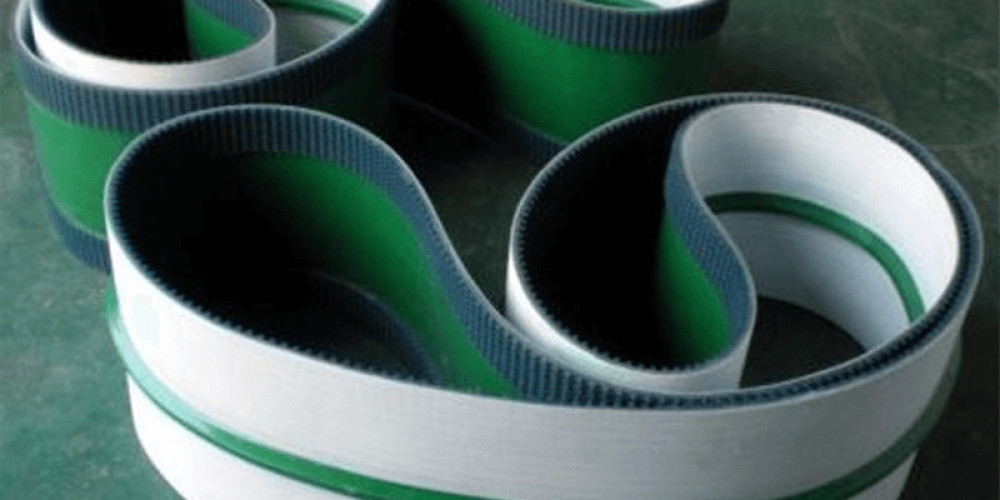

In food processing, industrial conveyor belts must meet core requirements: hygiene, oil resistance, and easy cleaning. Polyurethane (PU) belts emerge as the optimal choice due to their non-toxicity, oil resistance, and cleanability, complying with FDA food-grade standards.

- Bakery Applications: PU belts with anti-slip textures (herringbone/chevron patterns) prevent dough slippage in steamed bun, bread, and mooncake production.

- Baking Machinery: Oil-resistant anti-slip belts for bread/cake machines ensure operational efficiency through anti-sticking and cut-resistant properties.

- Meat Processing: Antimicrobial easy-clean belts withstand grease contamination while enduring high-frequency sanitization cycles.

II. Mining Machinery Industry Solutions

Mining operations demand conveyor belts with extreme load capacity, wear resistance, and corrosion protection:

- Steel Cord Reinforced Belts: Preferred for long-distance, high-capacity transportation due to superior tensile strength (>5000 N/mm) and impact resistance.

- Mobile Systems: Deployed in open-pit mining for frequent relocation.

- Fixed Systems: Enable continuous ore transportation in main channels.

- Tubular Conveyor Systems:

- Utilizes enclosed belt designs to suppress dust emissions.

- High-strength belts withstand vertical lifting forces in steep-angle scenarios.

- Chemical Resistance: Acid/alkali-resistant belts extend service life in tailings processing by resisting corrosive slurry.