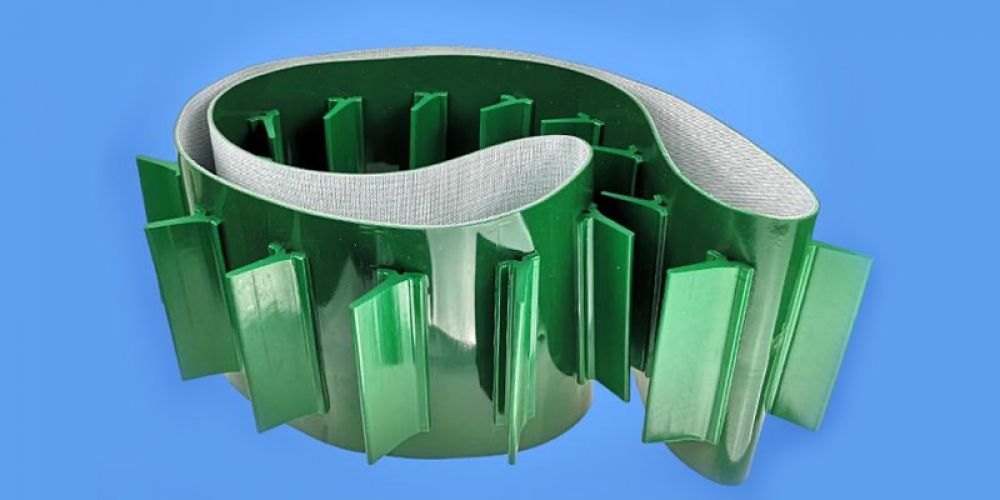

The material control function of the straight plate baffle is mainly achieved through the following aspects:

Physical isolation: straight plate baffles are usually used to divide the material flow into different areas or channels, so as to achieve the separation and orderly flow of materials. This physical isolation can prevent material mixing or overflow, and improve the stability and controllability of the production process.

Directional guidance: straight plate baffles can be set at key positions in the material flow path to guide the material to flow in a predetermined direction. This helps to ensure that the material maintains the correct direction and sequence during transportation, processing or storage.

Speed control: By adjusting the friction coefficient between the straight plate baffle and the material or the angle of the baffle, the flow speed of the material can be controlled to a certain extent. This is very useful for production processes that require precise control of the material supply rate.

The material guidance methods of curved or folding baffles in the turning area are as follows:

Gradual guidance: In the turning area, the design of curved or folding baffles usually follows a gradual curvature radius, so that the material can smoothly follow the bend of the baffle and turn. This helps to reduce the resistance, scattering and blockage of the material during the turning process.

Centrifugal force control: When the material flows at a certain speed in the turning area, centrifugal force is generated. The design of curved or folded baffles can utilize this centrifugal force. By reasonably setting the height, angle and curvature radius of the baffle, the material can flow close to the inside of the baffle, thereby achieving effective turning guidance.

In addition to straight plate type and curved or folded baffles, there are other types of baffles, such as:

Inclined baffles: This type of baffle is usually set on the slope of material flow, using gravity to guide the material to flow downward or upward. Inclined baffles can effectively control the flow speed and direction of materials.

Grid baffles: Grid baffles are composed of a series of crisscrossing rods to form a grid-like structure. This baffle can allow air or liquid to pass while maintaining material flow, and is suitable for occasions where ventilation or drainage is required.

Adjustable baffles: Adjustable baffles have the function of adjustable height, angle or position, and can flexibly adjust the position and shape of the baffle according to production needs to adapt to different materials and process requirements.