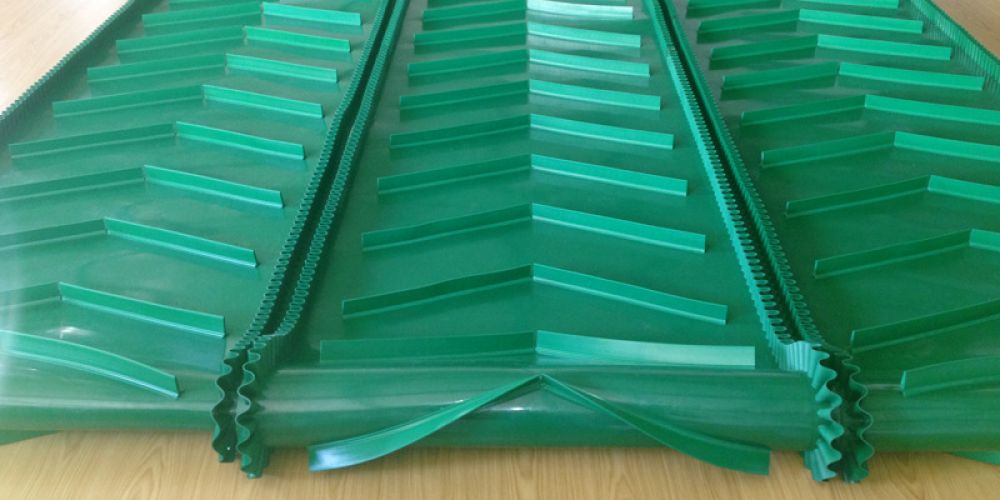

There are indeed many specifications of baffles in industrial belts, including straight baffles, oblique baffles and special-shaped baffles. The main function of these baffles is to prevent items from sliding off the conveyor belt and to support the conveyor belt at the curved part of the conveyor belt to keep it running stably.

Straight baffles are the most common type of baffles. Their shape is parallel to the conveyor belt and are mainly used to prevent items from sliding off the conveyor belt. Oblique baffles are installed at a certain angle to the conveyor belt and are usually used in the part where the conveyor belt turns or changes direction to support the conveyor belt and prevent it from deforming. Special-shaped baffles are customized according to actual needs and can be adapted to various special applications.

In addition to different specifications of baffles, industrial belts also have a variety of different materials and structures to choose from. For example, common industrial belt materials include rubber, PU, PVC, etc., and suitable materials can be selected according to different application requirements. In addition, industrial belts can also be divided into three types according to the type of belt core: wire rope core, fiber core and wire core. Each belt core has its unique advantages and applicable occasions.

Choosing the appropriate specifications and materials of industrial belt baffles requires comprehensive consideration based on actual application requirements to ensure that the belt can operate normally and stably and extend its service life.

Special-shaped baffles may be used in the following special applications:

Occasions where items need to be prevented from slipping: The design of special-shaped baffles can better adapt to items of various shapes and sizes to prevent them from slipping off the conveyor belt during transmission.

Occasions where special bending is required: In some occasions where the conveyor belt needs to be specially bent, such as curved conveying paths or curved conveyor belts, special-shaped baffles can better support the conveyor belt and maintain its stable operation.

Occasions where special changes are required: In occasions where the conveyor belt needs to change direction, such as changing the running direction of the conveyor belt or adjusting the position of the conveyor belt, special-shaped baffles can better adapt to the needs of changing direction and maintain the stable transmission of items.

Occasions where special needs need to be adapted: In some special industrial applications, such as those requiring high strength, high wear resistance, high temperature resistance or corrosion resistance, special-shaped baffles can be customized to meet these special needs and improve the performance and life of the conveyor belt.

In short, special-shaped baffles have unique advantages and applicability in various special applications, and can be customized according to actual needs to meet working requirements in various complex environments.