1. Introduction

With the development of modern industry, conveyor belts are increasingly used in various fields, such as food, medicine, chemical industry, electronics, etc. However, during the use of conveyor belts, various problems often occur, such as the falling and damage of materials conveyed by the conveyor belts. In order to solve these problems and improve the service life and operating efficiency of conveyor belts, PU conveyor belt baffles came into being. This article will give a detailed introduction to the principle, characteristics, classification and application of PU conveyor belt baffles to help you better understand and use PU conveyor belt baffles.

2. Principle and characteristics of PU conveyor belt baffles

1. Principle

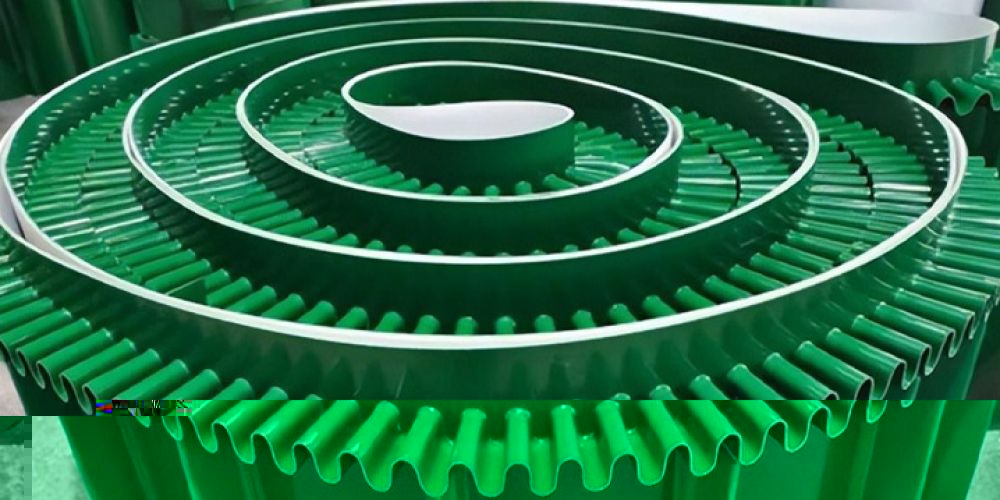

PU conveyor belt baffles are a hard material welded on both sides of the conveyor belt. Its main function is to prevent the conveyor belt from falling and breaking during operation. The working principle of PU conveyor belt baffles is to block the material so that the material is evenly distributed on the conveyor belt, thereby ensuring the normal operation of the conveyor belt.

2. Characteristics

(1) Wear resistance: PU conveyor belt baffles are made of high-strength and high-wear-resistant materials. They have high impact resistance and wear resistance and can effectively extend the service life of the conveyor belt.

(2) Anti-corrosion: PU conveyor belt baffles have good anti-corrosion properties and can maintain good performance in wet or corrosive environments.

(3) Anti-skid: The surface of PU conveyor belt baffles has been specially treated and has a good friction coefficient, which can effectively prevent materials from slipping on the conveyor belt.

(4) Easy to clean: PU conveyor belt baffles have a simple structure, are easy to disassemble and clean, and can keep the conveyor belt clean and hygienic.

III. Classification of PU conveyor belt baffles

According to the structure and purpose of the baffle, PU conveyor belt baffles can be divided into the following categories:

1. T-type baffle: T-type baffle is the most common baffle form, mainly used to evenly distribute the conveyed materials.

2. S-type baffle: S-type baffle can prevent the transported materials from falling and has good elasticity and cushioning properties.

IV. Application of PU conveyor belt baffles

PU conveyor belt baffles are widely used in many fields such as food, medicine, chemical industry, electronics, etc., such as beverage factories, pharmaceutical factories, flour processing factories, electronics factories, etc. By using PU conveyor belt baffles, problems such as conveyor belt deviation and slipping can be effectively solved, and the service life and operating efficiency of the conveyor belt can be improved. In addition, PU conveyor belt baffles also have good environmental performance and can reduce the scattering and pollution of materials during transportation.

V. Conclusion

In short, PU conveyor belt baffles, as an important auxiliary component of conveying equipment, are of great significance to improving the service life and operating efficiency of conveyor belts. I hope this article can provide you with a comprehensive understanding of PU conveyor belt baffles and provide you with a useful reference during use.