With the continuous development of all walks of life, conveyor belts are increasingly widely used in various industries. Among them, light conveyor belts have become an indispensable part of various industries due to their lightness, durability and high efficiency. This article will introduce in detail the types, characteristics, usage methods and maintenance of light conveyor belts.

1. Types of light conveyor belts

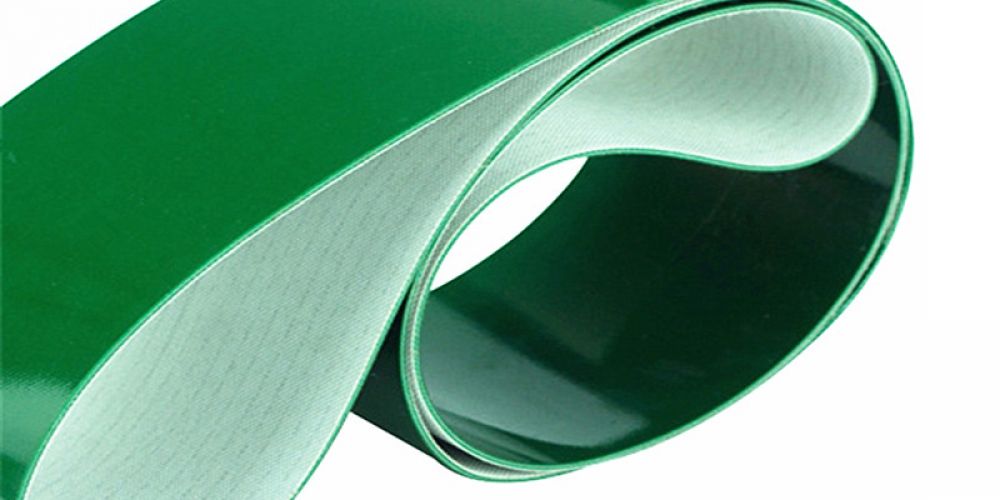

1. Flat conveyor belt: The surface of the flat conveyor belt is smooth and suitable for conveying materials on a flat surface, such as food, medicine and other delicate items.

2. Patterned conveyor belt: The surface of the patterned conveyor belt has uneven patterns, which can increase the friction between the conveyor belt and the material, and is suitable for conveying heavier items.

3. Ring conveyor belt: The ring conveyor belt consists of a series of rings, which is suitable for conveying ring-shaped objects or long-distance conveying.

4. Corrugated conveyor belt: The surface of the corrugated conveyor belt has a wave-shaped design, which can prevent the material from sliding during the conveying process, and is suitable for conveying items that are easy to slide.

2. Characteristics of light conveyor belts

1. Lightweight: The main materials of light conveyor belts are polyester, nylon and other lightweight materials, so they are light in weight and easy to carry and install.

2. Durable: Light conveyor belts are made of special production processes and high-quality materials, with high tensile strength and wear resistance, and long service life.

3. Efficient: Light conveyor belts can be customized in length and width as needed to meet the needs of different working conditions; at the same time, their high-speed operation characteristics make the conveying efficiency high.

4. Safety: Light conveyor belts have an anti-slip design, which can effectively prevent materials from sliding during operation and ensure safe production.

3. How to use light conveyor belts

1. Installation: When installing, the light conveyor belt should be placed on a flat ground to avoid tilting or unevenness. At the same time, ensure that the gap between the conveyor belt and the supporting wheel is moderate to ensure normal operation.

2. Adjustment: During use, if the conveyor belt is found to be deviated or too tight, it should be adjusted in time. When adjusting, the operation should be carried out in accordance with the requirements of the instructions to avoid damaging the conveyor belt or affecting the use effect.

3. Cleaning: Regular cleaning and maintenance of light conveyor belts can effectively extend their service life. When cleaning, use a soft cloth or clean water to wipe, and avoid using hard objects to scratch the surface of the belt.

IV. Maintenance of light conveyor belts

1. Regular inspection: During use, the light conveyor belt should be inspected regularly, and replaced in time if damage, aging, etc. are found. At the same time, check whether the supporting wheels, rollers and other parts are seriously worn. If there are any problems, repair or replace them in time.

2. Avoid overload: When using light conveyor belts, long-term overload operation should be avoided to avoid excessive stretching or damage of the conveyor belt.

3. Avoid impact: During transportation, strong impact or collision on light conveyor belts should be avoided to avoid damage to them.

Light conveyor belts have been widely used in various industries due to their lightness, durability and high efficiency. After understanding its types, characteristics, usage methods and maintenance knowledge, we can better use this equipment to facilitate our work.